Product

FERRO temperature measuring ring (PTCR) in the United States

Acting as the agent of thermal insulation materials and heating elements for high temperature kilns in Germany, JFCC temperature measuring blocks in Japan, FERRO temperature measuring rings in the United States, Bullers temperature measuring rings and coins in the United Kingdom, as well as Private label 1800 ℃ high temperature ceramic fiber binder

Classification:

Keywords: temperature measuring materials, refractory materials, heating materials

Ferro (PTCR) Process Temperature Control Rings

Accurate and effective temperature measurement is required in the production of ceramic products, but most measurements are limited in time and space. For example, thermocouples cannot measure the temperature of the product itself, but the ambient temperature of the product. In addition, it can only measure radiant heat, and does not involve conduction heat from kiln furniture. PTCR high-precision ceramic firing temperature indicator is used to record the real firing process of fired products (including radiant heat and conduction heat).

1. Temperature measuring ring function

In addition to the formula, the performance of electronic ceramic products is determined by the firing process. The comprehensive thermal effect of ceramic firing generally includes: firing temperature, holding time and kiln atmosphere. A variety of kilns are used in the production of industrial products and practical research, such as box furnaces, tube furnaces, vertical kilns, tunnel kilns, bell kilns, roller kilns, etc. Electronic ceramics, magnetic materials, and powder metallurgy heat treatment all require precise and effective temperature control. However, most temperature measurement methods (such as thermocouples, fire cones, photometers, etc.) are limited in time and space. In actual use, they can only measure the ambient temperature of the product, and it is difficult to measure the conduction heat and radiation heat from different directions and the cumulative thermal effect of the product itself for different holding times. In fact, the comprehensive thermal effect in the production of ceramic products will directly affect the firing quality of the product. Using the temperature measuring ring can not only solve the limitation of time and space, but also measure the radiant heat and conduction heat of the kiln and the comprehensive thermal effect of the entire firing process of the product at the same time.

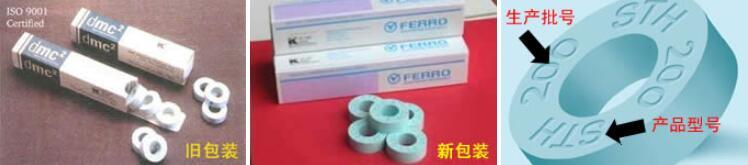

The entire production process of PTCR of Ferro Co., Ltd. in the United States has obtained ISO9002 quality certification. From various aspects (original selection of production process control, formulation of product inspection conversion table) to ensure that the product is absolutely accurate, reliable and convenient.

2、 Ferro PTCR temperature measuring ring 560-1750 ℃ ceramic temperature measuring ring product introduction

Many high-temperature refractory products require precise and effective measurement of kiln temperature during the production process, but most measurement methods and tools are limited in time and space. For example, thermocouples cannot measure the temperature of the product itself, but rather the ambient temperature at which the product is fired. The temperature recorded by a thermocouple at the top is only a point in space and time, and a thermocouple cannot determine the heating process; A thermocouple cannot provide information on whether the furnace is uniformly heated in different directions. It can only measure radiant heat and does not involve heat transfer from the kiln furniture.

FERRO PTCR ceramic temperature measuring ring is a high-precision ceramic temperature indicator that faithfully records the thermal process experienced by the product during the firing process.

FERRO PTCR ceramic temperature measuring ring can not only measure radiation heat and radiation heat, but also consider the impact of temperature over time.

FERRO PTCR ceramic temperature measuring ring can conveniently represent the heating process with a simple number - ring temperature (RT), making it easy to apply in practical work.

The temperature measuring ring is widely used in continuous and non continuous tunnel kilns, shuttle kilns, roller kilns, bell kiln, etc. It is recommended to use multi position and multi level placement, which can provide you with the most direct understanding of the heat distribution inside the kiln.

At the same time, the FERRO PTCR temperature measuring ring can be used in different firing atmospheres such as oxygen, nitrogen, air, vacuum, and reduction.

There are eight models of ceramic temperature measuring rings available for users to choose from, with a temperature range of 560-1750 ℃. They can be distinguished based on the color of the temperature measuring ring, the production batch number and product code printed on the ring.

三、Ferro PTCR测温环的工作范围、型号及应用行业

| temperature range | model | color | Application industry |

| 560~660°C | PTCR-ZTH | gray (primary color is blue) | Sales started in June 2017 |

| 600~850°C | PTCR-ATH | gray | Sales start on January 1, 2023 |

| 660~900°C | PTCR-UTH | yellow | Low-temperature refractory materials, daily-use porcelain, art ceramics, glazes, magnetic materials and kiln furniture |

| 850~1100°C | PTCR-ETH | light green | Low-temperature refractory materials, daily-use porcelain, art ceramics, ceramic tiles and kiln furniture |

| PTCR - ETL | |||

| 970~1250°C | PTCR—LTH | pink | Porcelain pre-synthesis, ceramics, bricks and tiles for construction, low temperature refractory materials and kiln furniture |

| PTCR-LTL | |||

| 1130~1400°C | PTCR—STH | green | Single-layer and multi-layer capacitors, ferrite and insulating ceramics, sanitary ceramics, powder metallurgy, household porcelain, bricks and tiles, grinding wheels, medium temperature refractory materials and kiln furniture |

| PTCR - STL | |||

| 1340~1520°C | PTCR—MTH | cream color | Magnetic materials, insulating ceramics, porcelain, dielectric ceramics, piezoelectric ceramics, semiconductor ceramics, other optical functional ceramics, biological and chemical functional ceramics, medium to high temperature refractory materials, kiln furniture |

| PTCR - MTL | |||

| 1450~1750°C | PTCR—HTH | White | Special structural ceramics, special functional ceramics, substrates, high temperature refractory materials and kiln furniture |

4、 Ferro PTCR temperature measuring ring size and packaging

PTCR temperature measuring ring size: outer diameter: 20mm, inner diameter: 10mm, thickness: 7.0mm.

PTCR is a reliable high-precision product with a maximum error of less than 3 ℃. It can even reach 1.5 ℃.

Product packaging: 15 pieces/small paper box, 600 pieces/large box.

5、 The working principle and usage method of Ferro PTCR temperature measuring ring:

1. The FERRO PTCR temperature measuring ring has recognized accuracy and reliability. The temperature measuring ring can be placed almost anywhere in the kiln, inside the furnace body, on the push plate or conveyor belt, and there is no need to measure the temperature before use;

2. The working principle of FERRO PTCR ceramic temperature measuring ring is to provide the actual accumulated heat of the temperature measuring ring and the fired product based on its linear shrinkage within the working temperature range. The test temperature is obtained by comparing it with the conversion table. After firing, the temperature measuring ring is removed and marked;

3. When the FERRO PTCR ceramic temperature measuring ring is heated in the kiln, it contracts and continues to contract at the highest temperature as the insulation time increases. Within its temperature range of use, the shrinkage rate is linear, providing a practical measurement method for the heating amount received by FERRO ceramic temperature measuring rings and fired products; The shrinkage (decrease in ring diameter) can be measured with a digital micrometer, which is used to record the diameter of each temperature measuring ring to the nearest 0.01mm;

4. The measured diameter of the temperature measuring ring can be converted into an equivalent temperature by referring to the outer diameter and temperature comparison table attached on the packaging, as well as the temperature correction curve (provided with the product).

Please note that for the sake of accuracy and convenience when using FERRO temperature measuring rings, each temperature gauge is specially designed for that batch of temperature measuring rings, and the production batch number marked must be consistent with the temperature conversion table.

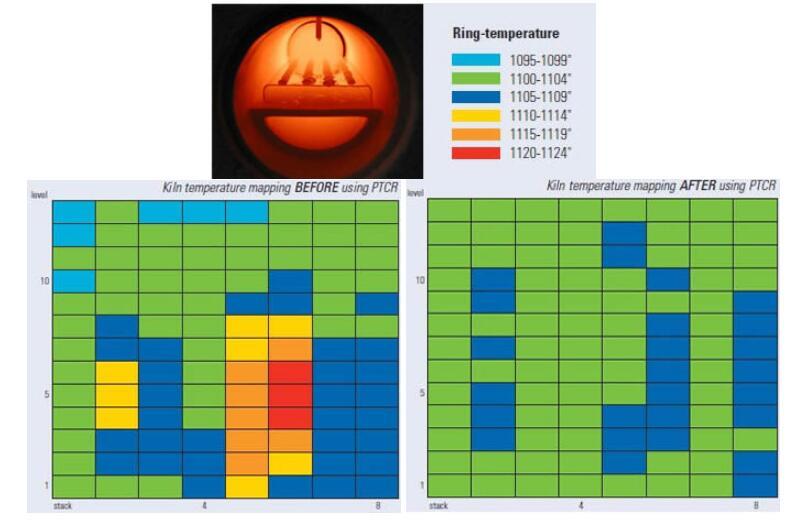

6、 Temperature distribution diagram of furnace measured by Ferro PTCR temperature measuring ring

The temperature measuring ring is widely used in continuous and non continuous tunnel kilns, shuttle kilns, roller kilns, bell kiln, etc. It is recommended to use multi position and multi level placement, which can provide you with the most direct understanding of the heat distribution inside the kiln.

FERRO PTCR temperature measuring ring can be applied in different firing atmospheres such as oxygen, nitrogen, air, vacuum, and reduction.

7. Advantages of applying FERRO temperature measuring ring to kilns:

1. FERRO temperature calibration ring/temperature measuring ring is flexible and flexible, and can easily and conveniently measure any corner of the three-dimensional space temperature distribution in the furnace.

2. It is best to place the FERRO temperature calibration ring/temperature measurement ring close to the actual heating state of the product, so as to accurately measure the actual heating state of the fired product.

3. The FERRO temperature calibration ring/temperature measurement ring has good consistency, which can ensure the good reproducibility of the product firing system, thereby improving the qualified rate of the finished product.

4. The use of FERRO temperature calibration ring/temperature measuring ring can reduce or even eliminate the need for measuring or destructive tests on the geometry, density and porosity of fired products. Thereby reducing the cost of quality control in the production process.

5. FERRO temperature measuring ring The ceramic temperature measuring ring is a reliable high-precision product with recognized accuracy and reliability, and the precise temperature difference reaches 1.5-3°C.

8. Cases of using temperature measuring ring to improve the quality of kiln fired products

1. Application of temperature measuring ring in the production of electronic ceramic products

Whether it is electronic ceramic powder or electronic ceramic components such as capacitors, resistors, and inductors, the requirements for electrical performance are high. When the recipe and production process are relatively fixed, the cumulative thermal effect of fired products is a factor that directly affects the electrical properties of the product, and the thermal effect is mainly a comprehensive reflection of firing temperature, holding time and firing atmosphere.

Different firing temperatures, holding times and firing atmospheres will sinter products with different properties; the same batch of products may be fired at different positions of the furnace for the same holding time to produce products of different quality. In actual production, it is difficult to directly judge or select good products from the production process and put them into the production of the next process, so that the defective rate of the produced products is likely to be out of control. However, the temperature measurement points of various existing kilns are relatively fixed, and the distribution of actual detection points of thermocouples is also limited, which is not conducive to accurately grasping the true state of the product during firing.

In addition, even if the temperature error caused by thermocouples of different materials and different old and new thermocouples is ignored, the thermocouple can only measure the radiant heat at the firing temperature, and cannot measure the conduction heat of the kiln furniture, the specific holding time and the comprehensive thermal effect of the actual firing atmosphere. At this time, if a few temperature measuring rings are placed before or during firing, not only the actual temperature in the furnace can be measured and the furnace temperature can be adjusted in advance, but also the actual thermal effect of product firing can be reflected according to the diameter, color depth and shape change of the temperature measuring ring after being fired.

The temperature measuring ring is small in size and easy to use. Not only can the products sintered in different kilns be compared horizontally, but also the samples and data of the temperature measuring ring after testing can be saved to make longitudinal comparisons of products sintered in different periods. This provides a real historical basis for product quality tracking and ensures strict management of product quality.

2. Use the temperature measuring ring to solve the problem of large lateral temperature difference in the kiln

The lateral temperature difference of the kiln is too large, which will easily lead to color difference defects in the same row of the kiln. This color difference is often in a gradual transition shape, and it is generally difficult to distinguish. The wider the kiln, the more obvious this defect. In fact, there are many solutions to the temperature difference problem. The challenge is how to accurately know the temperature difference at different positions in the kiln. The test proves that in the production of polished tiles, the lateral temperature difference in the firing zone of the kiln should be controlled as much as possible to ≤5°C.

Commonly used temperature measuring equipment such as temperature measuring thermocouples are only installed on one side of the kiln, and it is difficult to detect and control the lateral temperature difference, so it is difficult to achieve uniform lateral temperature. And by using the temperature measuring ring, because of its small size, it can accurately measure the kiln temperature at different positions, and obtain the accurate value of the temperature difference in the kiln. On the one hand, it makes up for the shortage of thermocouples, and on the other hand, it measures the heat distribution in the three-dimensional space of the kiln.

Then, by reasonably setting the air-oil (gas) ratio of each burner, correctly adjusting the valve opening, and adding refractory asbestos in time to prevent air leakage and poor heat dissipation from the kiln wall, it is much easier to solve the problem of temperature difference.

3. The application of the temperature measuring ring in the box-type electric furnace

The box-type electric furnace is widely used in the production of laboratories and small products. Because of its small investment and flexible use, it has become the first choice for firing equipment. Since electronic ceramics and modern fine ceramics are very sensitive to firing temperature, a temperature deviation of 3-5°C can cause significant differences in product performance, so it is very necessary to ensure the uniformity of temperature in the box furnace. In actual use, due to the different settings of the heating elements of the box-type furnace, the middle temperature is often relatively uniform, and the surrounding temperature is relatively unstable.

Under normal circumstances, the box-type furnace is equipped with thermocouples for temperature measurement, but due to the limitation of the space where the thermocouples are placed, the temperature of each point in the furnace cannot be measured, so the distribution of temperature differences in the furnace cannot be ascertained. As for how to place the fired products, it is reasonable to carry out more tests, but the temperature difference will also change after the number or variety of products placed in the furnace changes. Therefore need a kind of simple, convenient means to measure the temperature of every corner in the furnace at any time.

The temperature measuring ring is small in size, a small ring of 20mm*7mm. Use a few pieces, place them anywhere in the furnace to be measured, measure their outer diameter after firing, compare the temperature table, and get the actual temperature of each point in the furnace. The measurement deviation is only within 3 degrees, which should be a good temperature measurement tool.

4. Application of temperature measuring ring in roller kiln

The firing of ceramic products in roller kiln needs to be carried out under a specific firing system. A reasonable firing system is the fundamental guarantee for obtaining good products. The firing system includes temperature system, pressure system and atmosphere system, among which the temperature system is the most critical. The temperature monitoring of the roller kiln mainly relies on the temperature data reflected by the thermocouple installed on the kiln roof or kiln side along the kiln length.

Roller kilns are generally divided into pre-tropical zone, firing zone and cooling zone. The detection of the temperature of the firing zone is mainly to determine the maximum temperature of the firing zone and the length of the high-temperature interval, that is, the time the product stays at high temperature. The maximum temperature of the firing zone is the highest temperature point of porcelain formation, which directly affects the raw firing and over-firing of the product. The length of the high-temperature zone affects the length of the holding time, which also affects the quality of the product. Therefore, precise control of firing temperature is the key to ensure product quality. Sometimes the temperature indicated by the thermocouple reaches the firing temperature of the product, but due to the difference in the holding time, the product will also have a big difference. The reason is that the thermocouple only measures the radiant heat at the position of the probe, and it is impossible to record the comprehensive thermal effects of the product due to the length of the holding time and the conduction heat generated by the kiln furniture.

The temperature measuring ring can record all the thermal effects accumulated by the product during the firing process. It can provide a product firing situation that is different from that reflected by equipment such as thermocouples. It is a better temperature measurement tool that is closer to the product and more truly reflects the heating of the product.

5. Application of temperature measuring ring in vertical kiln sintering electronic ceramics

Vertical kiln is widely used in sintering electronic ceramics due to its advantages of simple operation, uniform temperature and continuous sintering. For example: ceramic capacitors, PTC ceramic resistors, zinc oxide varistors, and PZT piezoelectric ceramics. The accuracy of the sintering temperature of these products is relatively high. If the temperature difference of similar products is too large during the sintering process, it will not only affect the consistency of the product, but also easily lead to the scrapping of the entire batch of products.

The thermocouple probes of vertical kilns are generally arranged outside the furnace, and the measured temperature is not the actual sintering temperature of the product. This requires not only knowing the theoretical sintering temperature of the product before sintering, but also knowing the difference between the actual temperature in the furnace and the temperature of the gauge head. Otherwise, it is difficult to burn high-quality products with the gauge temperature adjusted according to the theoretical temperature. At this time, use the temperature calibration ring to calibrate the temperature in the furnace in advance, which can not only reduce the waste of materials, but also save precious time for furnace testing.

The continuous sintering of the vertical kiln makes each furnace product invisible during the sintering process. In order to ensure the quality of the product after it comes out of the furnace, it is necessary to use a temperature measuring ring to monitor the sintering process of each batch of products. Considering that thermocouples, like other instruments and meters, will age or have low precision after a period of use, and the heating element itself is also prone to aging. Putting the temperature measuring ring regularly (for example, once a day) in the sintering of electronic ceramic products can monitor the furnace temperature changes of the sintered products. In the long run, the sintered products in the vertical kiln use the temperature calibration ring as a monitoring method to ensure the quality and consistency of the product.

6. Application of temperature measuring ring in magnetic materials

In the production and research and development of nickel-zinc, manganese-zinc-cobalt, neodymium-iron-boron and other magnetic materials, it is necessary to plan the firing temperature for the production process temperature (pre-sintering temperature) of new materials; the sintering of secondary magnetic material products also requires accurate kiln temperature in order to stabilize the electrical performance indicators of magnetic products. Kilns generally transmit the temperature of the kiln through thermocouples. However, due to factors such as different manufacturers, different kilns, and different specifications of thermocouples, it is difficult to unify the temperature measurement standard in the same enterprise.

The temperature measuring ring can accurately provide the actual temperature effect inside the furnace (that is, the cumulative thermal effect of the product), and can track the quality of the accumulated heat required by the magnetic material products. At the same time, it can objectively record the daily temperature changes in the furnace and provide accurate data information. As the archive data for temperature quality tracking, it is conducive to the implementation of the ISO quality tracking management system, the unification of internal R&D and production temperature control standards, and the reduction of the complexity of sintering temperature changes caused by different batches of raw materials.

Message

Filling in your phone and email information will help us to contact you in a timely manner and resolve the issues you have raised as soon as possible.